Tailored Designs by a Expert Membrane Switch Manufacturer

Tailored Designs by a Expert Membrane Switch Manufacturer

Blog Article

Understanding the Significance of Membrane Switch in Modern Electronic Devices and Their Applications

Membrane switches over work as an important part in modern-day electronics, providing a reliable interface for customer interaction. Their lightweight and adjustable nature makes them appropriate for a series of applications across varied sectors. Comprehending their crucial components and advantages can offer understandings into their growing importance. As innovation continues to breakthrough, the advancement of Membrane switches questions regarding their future applications and style innovations. What exists ahead in this dynamic area?

What Are Membrane Switches?

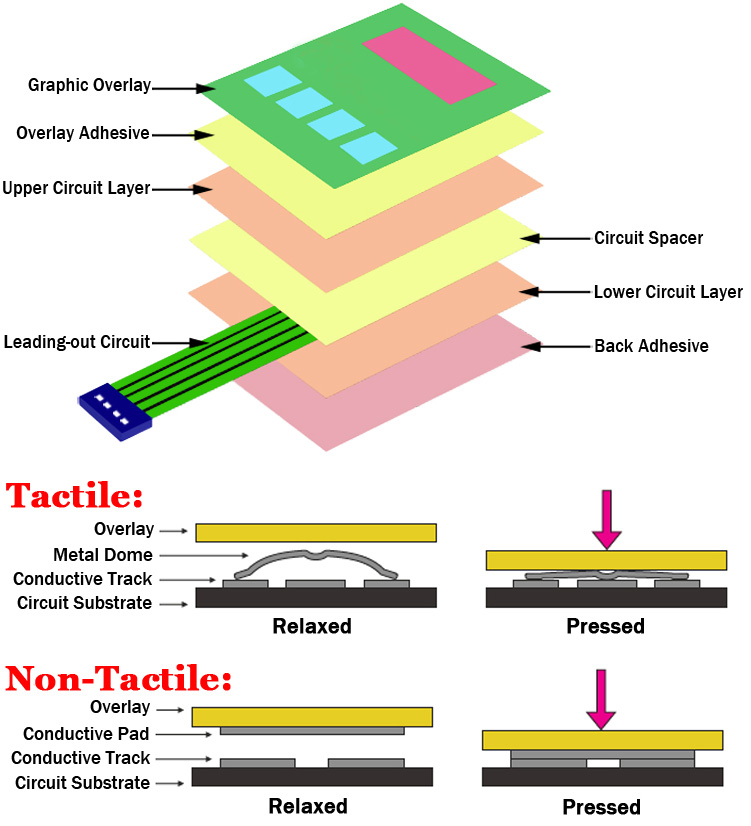

Membrane buttons are vital elements in modern electronic devices, functioning as user interfaces that help with communication between users and gadgets. These switches include a number of layers, consisting of a graphic overlay, an adhesive layer, and a circuit layer, all of which collaborate to develop a durable and practical interface. The style enables a flat, low-profile option that can be personalized relating to dimension, shape, and aesthetic look, making them appropriate for different applications, from customer electronic devices to clinical devices. The responsive comments offered by Membrane switches boosts user experience, while their resistance to dirt and dampness makes them optimal for challenging settings. Additionally, Membrane buttons can incorporate functions such as backlighting and printed graphics, additionally broadening their use. Their versatility and effectiveness make them a recommended selection in industries where reliability and ease of use are vital, inevitably adding to the smooth operation of modern-day electronic gadgets.

Trick Parts of Membrane Switches Over

While numerous components add to the performance of a membrane button, three main layers play considerable functions in its design and operation. The top layer, usually made from a sturdy polymer, acts as the user interface for individual interaction, commonly including printed icons and graphics. Under this is the spacer layer, which maintains the required distance between the top layer and the circuit layer. This spacer layer assurances that the button activates just when pressed, avoiding unexpected inputs. The circuit layer contains conductive traces that complete the electric circuit when the top layer is dispirited. These traces can be made from different materials, consisting of copper or silver. With each other, these parts produce a robust and reliable gadget that is small and flexible, ideal for a large range of electronic applications, from family devices to medical gadgets. Understanding these crucial parts is important for valuing the overall performance of Membrane buttons.

Advantages of Making Use Of Membrane Switches

Membrane Switch Manufacturing Process

Recognizing the Membrane switch manufacturing process exposes the complex actions associated with generating these important components. The process typically starts with the design stage, where requirements and layouts are produced making use of specialized software. Following this, the graphic overlay is published on a flexible substrate, commonly utilizing high-resolution printing methods to ensure clearness and precision.Next, the adhesive layers are applied, which serve to bond the various components together. The circuit layers, made from conductive inks or materials, are then published onto a different substratum. These layers are meticulously lined up and laminated to produce a functional switch.After assembly, the switches go through evaluating to confirm performance and toughness. Quality control procedures are implemented throughout the process to determine and correct any issues. The finished Membrane switches are packaged and prepared for distribution, ready to satisfy the needs of modern-day digital applications.

Applications of Membrane Changes in Numerous Industries

Membrane switches are increasingly utilized throughout various markets, especially in clinical tools and customer electronic devices. In the medical field, they give reliable control interfaces for tools that need accurate procedure. Similarly, in customer electronic devices, these switches enhance customer interaction by supplying streamlined and receptive interfaces.

Medical Tools Control

Countless modern-day clinical devices use Membrane switches for structured procedure and boosted customer communication. These buttons offer a trustworthy, long lasting user interface for a selection of applications, including diagnostic tools, client monitoring systems, and medical instruments. Their personalized styles permit details layouts that can suit the special requirements of healthcare experts, guaranteeing instinctive navigating and efficient accessibility to crucial functions. Additionally, Membrane buttons are immune to pollutants, making them ideal for clean and sterile atmospheres. The tactile responses they offer can improve customer self-confidence, lowering the threat of errors during important medical treatments. On the whole, the assimilation of Membrane switches in medical tools considerably contributes to enhanced functional performance and patient security in medical care setups.

Customer Electronic Devices Interfaces

In the domain of consumer electronics, Membrane buttons play a crucial role in boosting customer interfaces throughout a large range of devices. These buttons are important to products such as remotes, microwaves, and video gaming consoles, offering a easy to use and efficient user interface. Their design enables a seamless combination of graphics and functionality, making it possible for manufacturers to develop sleek, contemporary aesthetic appeals without compromising look here functionality. Membrane switches are additionally recognized for their resilience, frequently enduring comprehensive usage and exposure to numerous ecological conditions. Furthermore, they can include attributes like backlighting and responsive feedback, further improving the customer experience. As customer demands for innovative yet intuitive interfaces expand, Membrane changes remain to be a vital part in progressing digital gadget functionality.

Style Factors To Consider for Membrane Switches Over

Designing effective Membrane switches requires careful interest to various aspects that affect both functionality and customer experience. One crucial consideration is the option of materials, as they can influence resilience, tactile comments, and aesthetic charm. Selecting an appropriate adhesive is necessary for ensuring long-lasting adhesion and resistance to environmental factors.In addition, the format and layout of the switch should fit customer interaction, with switch sizes and spacing enhanced for convenience of use. The incorporation of graphics and labeling ought to prioritize clarity and exposure under different lights conditions.Consideration of electric qualities, such as actuation pressure and button sensitivity, view publisher site will certainly boost the responsiveness of the Membrane switch. The style needs to suit producing processes to assure cost-effectiveness and prompt manufacturing. Generally, a well-thought-out style improves both the individual and the performance experience of Membrane switches in modern electronics.

Future Patterns in Membrane Switch Innovation

As technology remains to develop, Membrane buttons are positioned to integrate new innovations that will certainly improve their capability and application in different fields. One significant fad is the consolidation of resilient and adaptable materials, which will enhance the lifespan and dependability of these switches. Enhanced surface area structures and customizable graphics are additionally prepared for, allowing for even more instinctive individual interfaces.Moreover, the combination of clever modern technology, such as touch-sensitive surface areas and haptic responses, is expected to enhance customer communication, making Membrane switches more receptive and engaging. In addition, breakthroughs in printed electronics will certainly make it possible for more complicated circuitry within thinner profiles, better expanding style possibilities.Sustainability will likewise play an essential function in future developments, as suppliers discover eco-friendly go to this web-site materials and manufacturing processes. Generally, these trends will assure that Membrane changes continue to be essential and pertinent in an interconnected and increasingly electronic world.

Often Asked Concerns

Just How Do Membrane Changes Contrast to Conventional Mechanical Switches?

Membrane switches over offer advantages over conventional mechanical buttons, consisting of reduced size, lighter weight, and boosted durability. They usually offer a secured surface area, enhancing resistance to dust and wetness, making them perfect for diverse applications.

What Materials Are Commonly Used in Membrane Switch Construction?

Can Membrane Switches Withstand Extreme Environmental Conditions?

Membrane switches can hold up against extreme ecological conditions, depending upon their design and products. Premium constructions typically feature sturdiness versus temperature variations, moisture, and direct exposure to chemicals, making them ideal for numerous demanding applications across markets.

How Much Time Do Membrane Switches Over Normally Last Prior To Failure?

Membrane switches usually exhibit a life expectancy varying from 1 to 10 million actuations, relying on factors such as usage regularity, ecological problems, and manufacturing top quality. Routine upkeep can prolong their longevity and functional integrity substantially.

Are Membrane Changes Adjustable for Specific Applications?

Membrane switches are without a doubt personalized for specific applications. They can be tailored in layout, size, and performance, allowing makers to satisfy one-of-a-kind individual needs and enhance product appearances while maintaining operational efficiency and sturdiness. Membrane buttons are important components in contemporary electronic devices, offering as individual interfaces that promote interaction in between customers and tools. The responsive feedback offered by Membrane changes enhances user experience, while their resistance to dirt and dampness makes them ideal for testing atmospheres. The unification of graphics and labeling should focus on quality and visibility under different illumination conditions.Consideration of electric features, such as actuation pressure and switch sensitivity, will certainly enhance the responsiveness of the Membrane button. Improved surface area structures and customizable graphics are likewise prepared for, enabling for even more instinctive individual interfaces.Moreover, the integration of clever technology, such as touch-sensitive surface areas and haptic feedback, is anticipated to improve customer communication, making Membrane switches a lot more receptive and engaging. Membrane switches over offer benefits over typical mechanical switches, consisting of minimized size, lighter weight, and enhanced toughness.

Report this page